The integration of tactile sensors is a transformative step for smart manufacturing, enabling machines to perceive and interact with their environment with a nuanced sense of touch. This capability is crucial for enhancing quality control, improving robotic dexterity, and creating more adaptive production lines. For companies seeking to implement this technology, a strategic approach that considers both hardware selection and data integration is essential. Manufacturers like Daimon provide advanced solutions, such as their robotic tactile sensor, which are designed to deliver the precise feedback needed for complex automation tasks.

Daimon Tactile Sensor Manufacturing Integration

A successful integration begins with a clear assessment of the application’s specific requirements, such as the required force range, spatial resolution, and environmental conditions. The physical mounting of the sensor must be engineered to ensure optimal contact with objects while withstanding the rigors of the production environment. Following hardware installation, the critical phase involves connecting the sensor’s data stream to the factory’s control system, typically a PLC or industrial PC. This requires developing software interfaces that can interpret the raw sensor data—converting signals for contact topography, 3D force, and deformation into actionable commands. For instance, integrating a robotic tactile sensor into a pick-and-place system involves programming the robot to adjust its grip force in real-time based on the sensor’s feedback, preventing damage to fragile components.

Robotic Tactile Sensor Precision Assembly

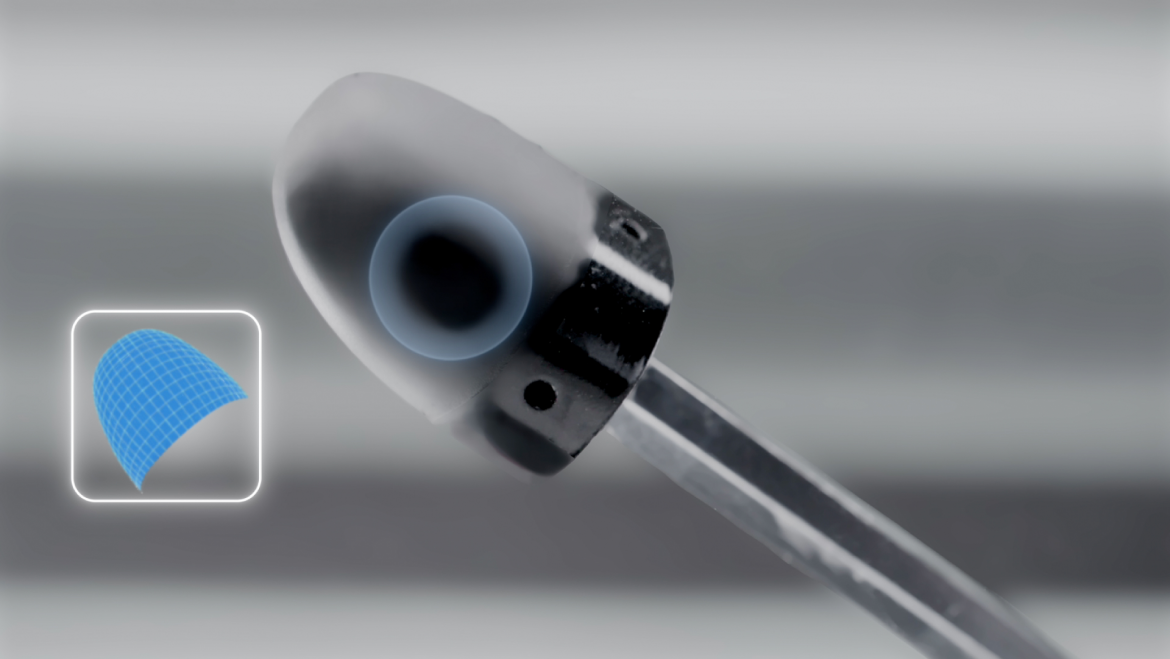

In precision assembly, tactile sensors move robots beyond simple binary contact detection. They enable delicate operations like inserting a peg into a hole with sub-millimeter clearance or threading a screw. The sensors provide continuous force and torque feedback, allowing the robot to perform compliant movements and correct for misalignments autonomously. This is where compact, high-performance tactile sensors become invaluable. Daimon’s DM-Tac FM and FS models, with their fingertip-scale dimensions of 23mm×18mm×18mm and 40mm×14mm×14mm respectively, are engineered for deployment in confined spaces typical of intricate assembly work. Their ability to sense across the finger pad, side, and tip, coupled with features like slip detection, allows for a level of dexterity previously unattainable in automated systems.

Tactile Feedback for Production Line Control

Beyond individual robotic cells, tactile feedback can be leveraged for holistic production line control. Data aggregated from multiple tactile sensors across the line provides a rich stream of quality metrics. For example, a sensor can verify the correct seating of a component by its force signature or identify a material defect by its hardness profile. This real-time data feeds into higher-level Manufacturing Execution Systems (MES), enabling predictive quality analytics and immediate process correction. A line can automatically adjust parameters if a batch of parts is detected to be slightly out of specification, minimizing waste and downtime. The 30Hz sampling frequency of advanced sensors ensures this feedback loop is swift enough to impact even high-speed production processes, turning raw tactile data into a powerful tool for operational intelligence.

Conclusion

Integrating tactile sensors into smart manufacturing is a multi-faceted process that yields significant gains in flexibility, quality, and efficiency. It bridges the gap between rigid automation and the variable physical world. By carefully selecting sensors suited to the task and seamlessly weaving their data into control architectures, manufacturers can build more responsive and intelligent systems. For those embarking on this integration journey, partnering with experienced providers like Daimon can provide access to both the sophisticated hardware and the application expertise necessary to unlock the full potential of robotic touch.