Ensuring product safety and compliance in the food industry is critical. Two technologies commonly used to detect contaminants are food metal detectors and X-ray inspection systems. While they serve a similar purpose—identifying unwanted materials in food products—they operate differently and are suited for different applications. Below, we explore the differences and how Foodman supports safety in food production.

How Food Metal Detectors Work

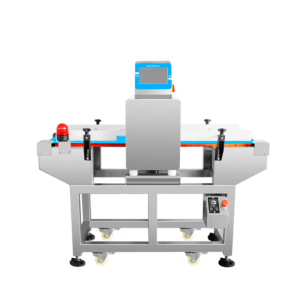

Food metal detectors use electromagnetic fields to identify metallic contaminants in food products. These systems are highly effective for detecting ferrous, non-ferrous, and stainless steel metals. They are typically installed on production lines to scan packaged or unpackaged products as they pass through.

This technology is ideal for identifying metal fragments from processing equipment, wire mesh, or broken machinery parts. Food metal detectors are generally more cost-effective than X-ray systems and are widely used across various segments of the food industry.

How X-Ray Inspection Works

X-ray inspection systems use radiation to scan products and create images similar to medical X-rays. These images help detect a range of physical contaminants, including glass, stone, bone, and some types of plastic, in addition to metal.

Unlike food metal detectors, X-ray systems can identify contaminants based on density rather than just conductivity. This makes them suitable for high-risk products or those in foil packaging, where metal detectors may be less effective.

Choosing the Right Technology for Your Facility

When deciding between X-ray inspection and a metal detector for food industry operations, consider the type of contaminants you’re targeting, your product packaging, and your budget. For most metal-related contamination risks, food metal detectors offer a reliable and efficient solution. However, if your products are prone to non-metallic contamination, an X-ray system may be more appropriate.

Foodman’s Role in Food Safety

Foodman offers a range of inspection solutions designed to meet the rigorous standards of the food industry. Our equipment helps manufacturers detect contaminants early in the production process, reducing recalls and protecting both consumers and brands.

From Metal to X-Ray: Making Informed Safety Decisions

Understanding the capabilities of food metal detectors versus X-ray inspection systems is essential for maintaining food safety. Each has its strengths, and choosing the right one depends on your specific production needs. With Foodman, food manufacturers gain access to trusted tools that enhance quality control and ensure regulatory compliance.