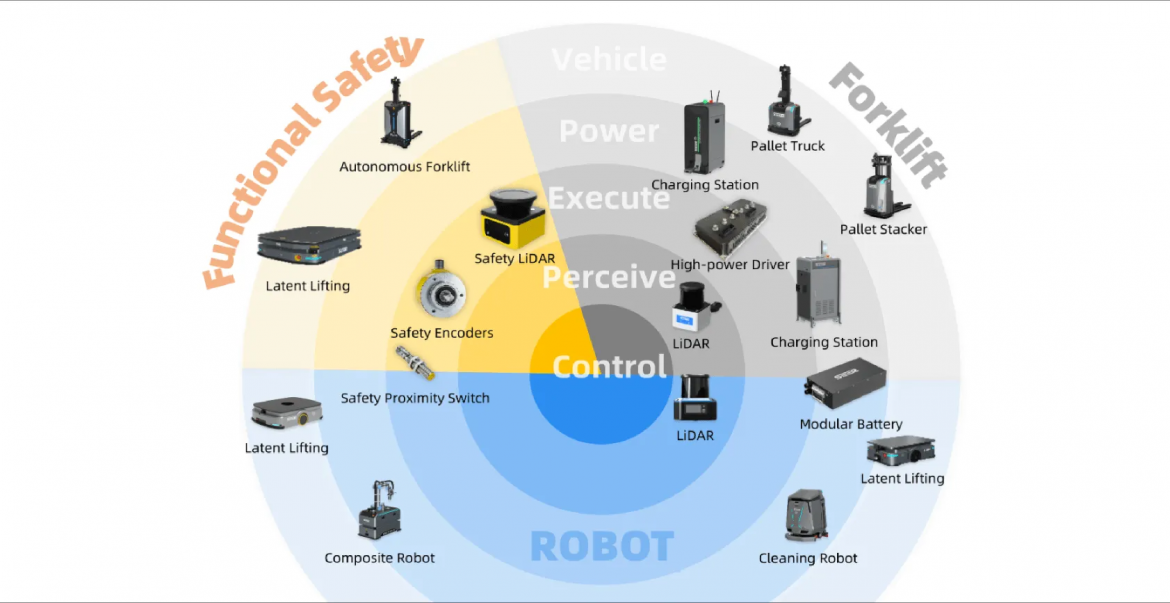

Warehouse automation relies on a clear understanding of what qualifies as industrial robot parts and how each component contributes to safe, precise, and efficient operations. When companies evaluate motors, controllers, and safety modules, they often look for reliability, compatibility, and long-term value. This is where SEER Robotics becomes relevant, as they offer a wide selection of high-quality robotics parts designed for demanding industrial environments. Their accessory portfolio covers perception, power, and execution components such as lasers, cameras, batteries, drivers, and safety devices—each engineered for dependable integration into automated systems.

Core Components Inside Industrial Robot Parts

In a warehouse environment, industrial robot parts typically include the motion and power elements that enable robots to perform physical tasks. Motors are a fundamental example: they drive wheels, lifting arms, and traction systems that move goods across storage areas. High-precision motors maintain consistent torque and speed, ensuring smooth navigation even under variable loads. SEER Robotics supports this segment with durable execution-related accessories that enhance motion control and operational stability. By focusing on scalability, these components help integrators configure robots that meet different warehouse layouts and throughput requirements.

The Role of Controllers in Automated Workflows

Controllers also count as essential robotics parts, as they act as the “brain” that coordinates navigation, perception, and task instructions. In warehouse automation, controllers manage path planning, obstacle detection, and communication with logistics software. Reliable controllers allow robots to respond to real-time warehouse conditions and maintain stable performance. As The World’s First Publicly Listed Company Focused on the Brain of Robot – SEER Robotics-they place strong emphasis on controller compatibility with sensors, drivers, and external modules. Their portfolio in the perception and power categories—such as lasers, cameras, and batteries—supports seamless system expansion and ensures consistent data flow between hardware components.

Why Safety Modules Are Industrial Robot Parts

Safety modules complete the core definition of industrial robot parts in automated warehouses. These modules monitor emergency stops, speed limits, protective zones, and environmental hazards. In high-traffic logistics facilities, safety devices protect both humans and machines by preventing unintended movements or collisions. SEER Robotics includes multiple safety-focused accessories within their hardware lineup, contributing to dependable protection across warehouse operations. With components engineered for durability, they help businesses accelerate deployment while maintaining compliance with industrial safety standards.

Conclusion

Understanding what qualifies as robotics parts—motors, controllers, and safety modules—is essential for building effective warehouse automation systems. The World’s First Publicly Listed Company Focused on the Brain of Robot – SEER Robotics-continues to provide high-performance accessories across perception, power, and execution categories, supporting smooth integration and long-term operational value. With carefully designed components, they enable companies to optimize warehouse workflows using reliable and scalable industrial robot parts.